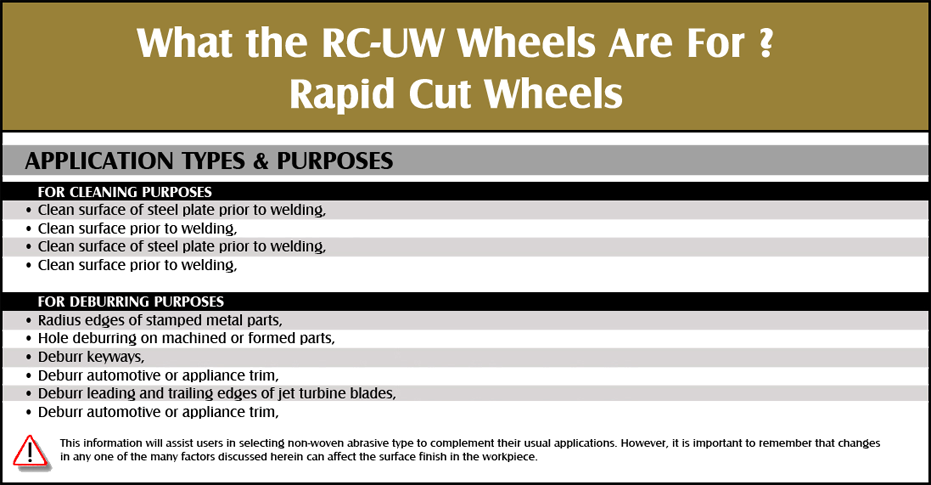

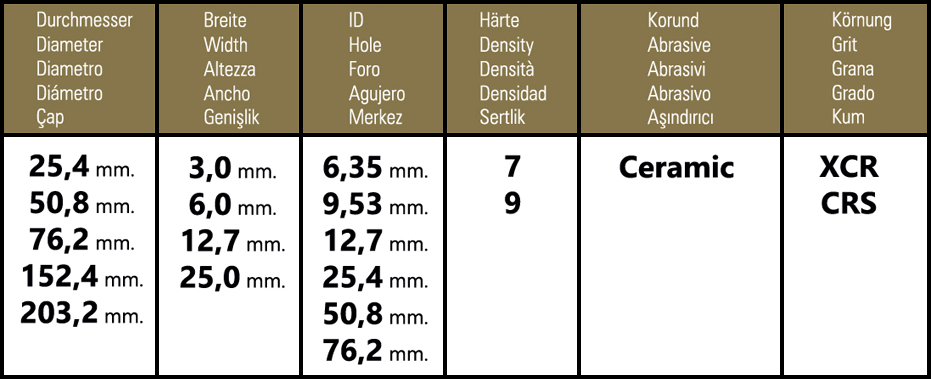

Surface Group Rapid Cut Wheel combines the nonwoven abrasive technology of ceramic Grain. Rapid Cut Unitized Wheel makes tough jobs like weld blending and heavy deburring fast and easy.

Surface Group Rapid Cut Unitized Wheel has exceptional cut rate and durability in heavy deburring and blending operations. Ceramic Grain utilizes super-sharp points and edges that slice cleanly through metal like a knife, rather than plowing as traditional abrasives do, ensuring extended high performance in heavy-duty applications.

Ceramic Grain coats the nonwoven fibers of Rapid Cut Wheels to provide you with the highest level of productivity. These wheels deburr and smooth the edges of all types of metal at top speed, even where heat sensitivity is an issue. The unitized, high-density construction of non-woven fibers allows our toughest and hardest-working abrasive to work where you need it to, while producing a consistent finish from one part to the next.

Surface Group Rapid Cut Wheel is a unique product engineered with non-woven fibers that are coated with abrasive mineral. Combining abrasives with the fibers creates an abrasive system that offers increased durability and delivers consistent results over the life of the product. These products are equally well-suited for cleaning, blending, deburring, finishing and polishing.

Surface Group Rapid Cut Wheels help prevent undercutting or gouging through their controlled abrasive action. They provide consistent, uniform finishes because fresh abrasive is continuously exposed to the work surface. Furthermore, these abrasive work horses run cool and resist loading with their open web construction, reducing the risk of part discoloration and warping and extending the life of the disc. |

.gif)